The procedure of the woodprep are the same as you all are familiar with, except we use our CNC as a 100% straight planer. We all know how difficult it is to get rid of a curve in a board. We use a 30mm planer bit for that, and just run it manually from the keyboard. We have the luxury of 2 big proff vacuum units, so set-up is a joke! All parts are thickness corrected on the CNC leaving 1 or 2 tenth mm for sanding.

Neck:

Top planed on CNC, Truss rod channel routed, with mark at nut for positioning the fretboard =1/2 hour

Fretboard are glued to neckblank, normal routine...

Fretboard radius, slots and inlay pockets, outline of neck and angle of head routed = 2-3 hours

The material are higher than the final size, so the rout don't cut through, and leave the neck with a wall of wood around!

I remove the waste from the neck, and we position a piece of 22mm MDF on the vacuum board, and rout the exact pocket for the fingerboard. Now the CNC knows where the neck is....

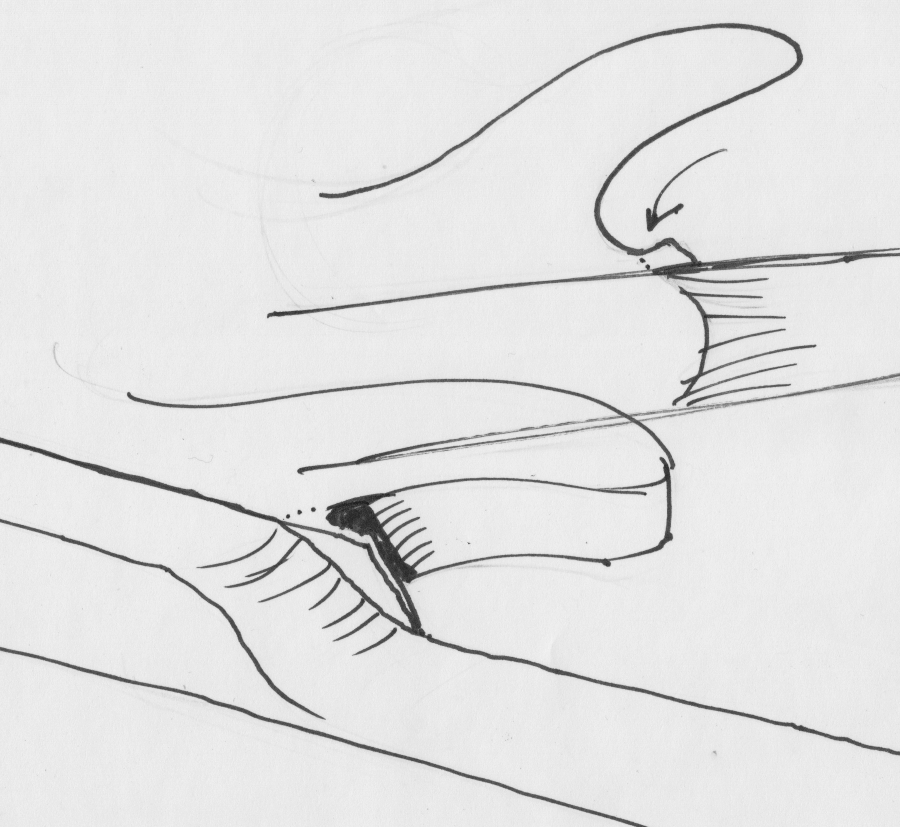

we position the neck, with the board in it's pocket, use doublestick tape to hold the in-body part and the head towards the MDF. At the head I cut a wedge that fits the angle.

Now we rout the back of the neck....rought with a 12mm flatbit and then a ballnose = 2-3 hours

Inlay and fretting, normal routine...

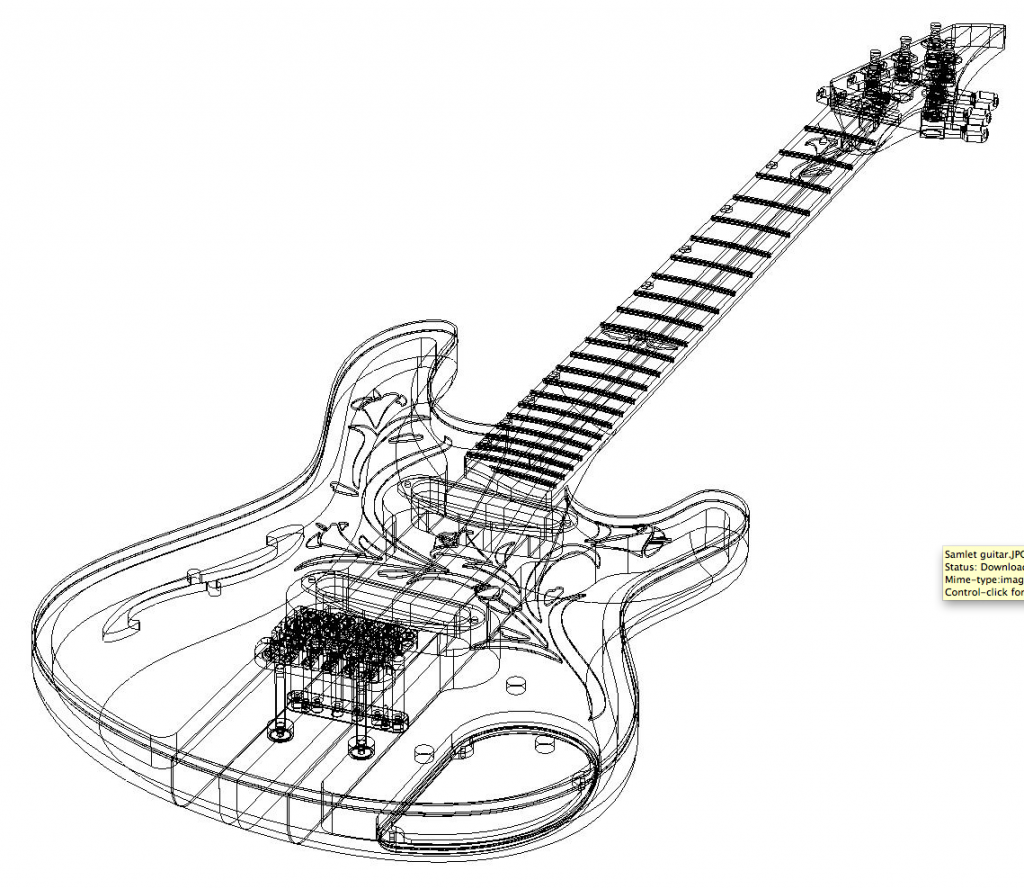

Body:

The two bodyparts are positioned with 2 spacers according to plans

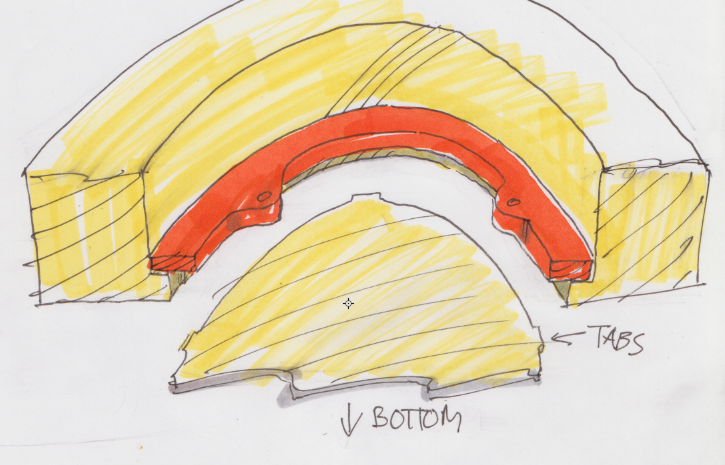

Backside routed, rough and ballnose, lid for electronic routed with a 0.6mm bit leaving a few tabs to hold it....for next process.

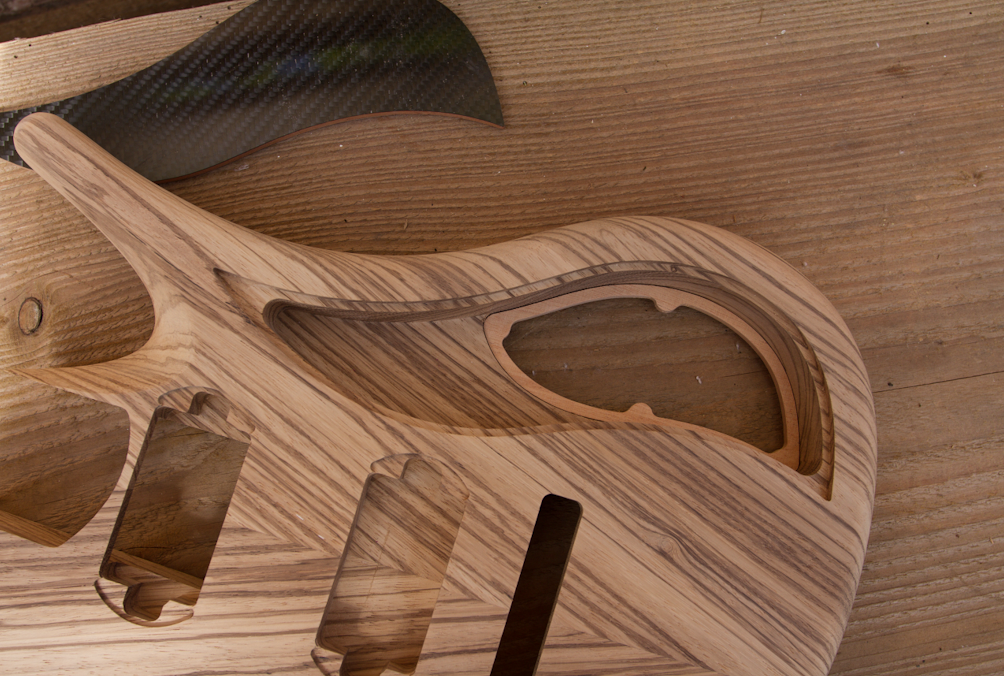

The channel for the neck are routed, still leaving the spacers in place. = 2-3hours

2 stripes of walnut are fitted/glued into the channel....normal routine

The channel are now routed to final size leaving a 1mm line of walnut in each side, body hollowed and the lid is freed from the tabs holding it. A lid-holder ring are routed, and glued into the body= 3 hours

Top glued on....normal...und so weiter...

A MDF board on vacuum are routed for 2 pieces of a stick, that are glued into the MDF and routed to fit the 2 holes in the spacers on the back of the body....now the coordinates are correct for the front rout, outline, binding and pockets and inlay = 3 hours

Routing Pearl inlays = 2 hours

Neck glued in and there will be 1/2 hour of blending the two parts together

Binding....usual business...first time for me...

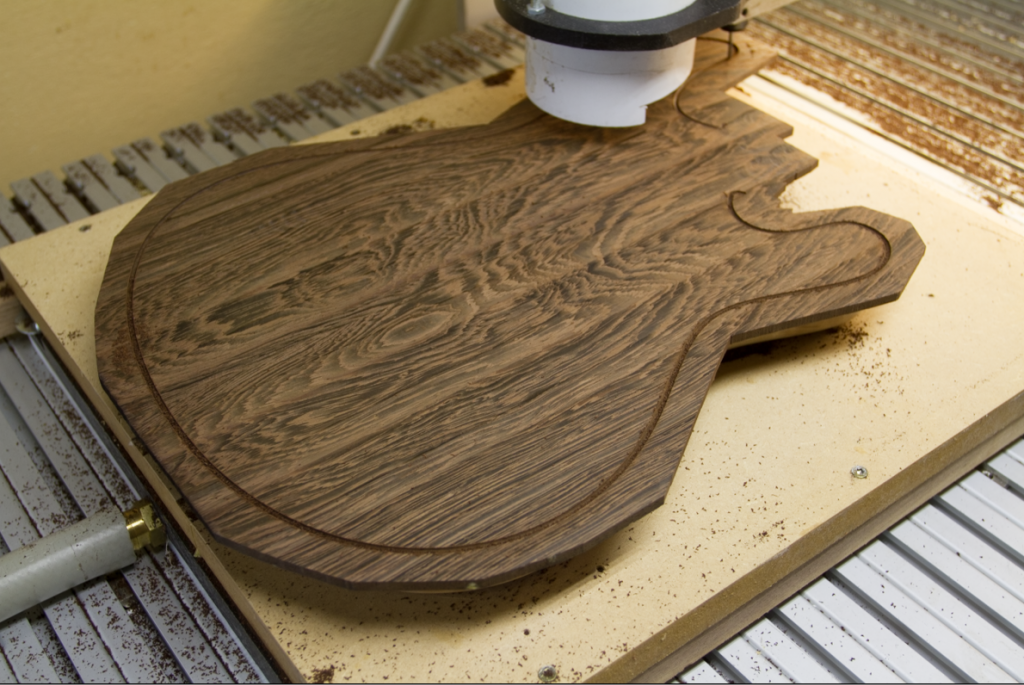

Sanding would be a couple of hours, as the CNC only leaves us with what we want to sand!

The shot is sharpened heavily to show what is left for sanding. It can be done finer, more time consuming, but this is where we want to stop.

BUT IMPORTANT the 17 hours are only "machine time" under ideal conditions, and no sudden changes in design.

All the drawing, Cad Cam and technical preparation are easy 14 hours, and don't include small ideas or changes.

The manual "normal routine" has to be added....whatever that is!

Hope this gives an impression of the work routine